Quench Oil Moisture Warning System

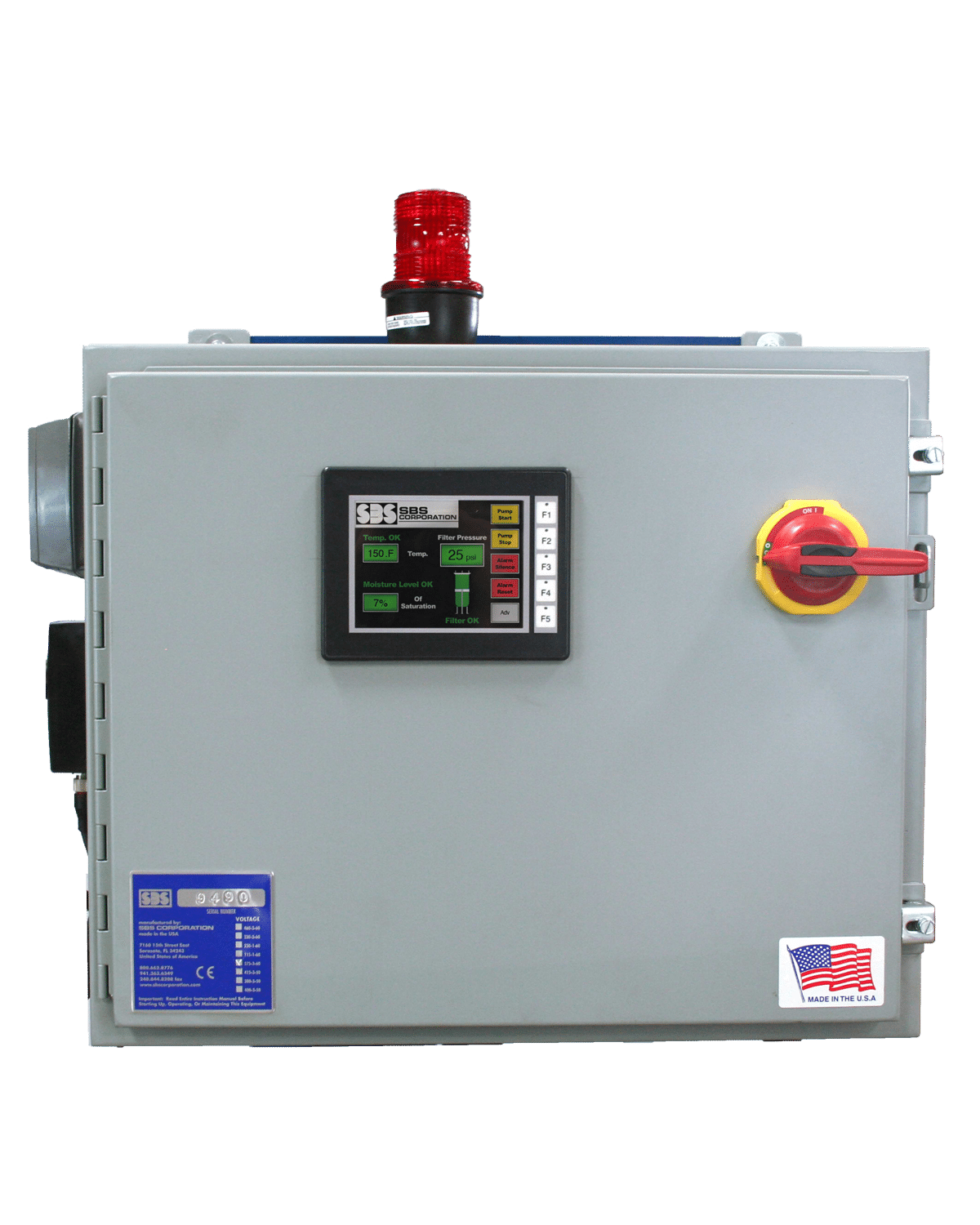

SBS Aqua-Sense

An AQUA-SENSE Quench Oil Moisture Warning System gives an early warning signal that moisture is migrating to a quench tank. This early warning, while water is still in a dissolved state, allows detection and correction to be made well ahead of what could become a very dangerous malfunction.

Monitoring moisture in your oil results in more consistent metallurgical qualities by eliminating shifts in the cooling curve. As moisture accumulates in a quench tank, the cooling characteristics of any given oil can be altered significantly. The AQUA-SENSE Moisture Monitor allows the setting of acceptable moisture limits and gives audio and visual alarms when those limits are exceeded.

The AQUA-SENSE is programmed to set off an alarm when it senses a sudden increase in the water content. High and/or rapidly increasing moisture levels disrupt the controlled quench process and create potentially hazardous conditions. Early detection allows time to discover and correct sources of moisture prior to reaching dangerously high levels. Better process control and the assurance of a safer workplace make the installation of an AQUA-SENSE Moisture Monitor an invaluable addition to any heat treating facility.

Features

A Safer Workplace

An undetected leak in a water-cooled heat exchanger, bearing, top cool section or even a building roof may lead to the accumulation of water in a quench tank. When hot steel hits water accumulated in the bottom of the tank, the water will turn to steam and drive the oil in the tank up into the heat chamber spilling fire out into the work area — a very dangerous occurrence. Early detection and correction will save the equipment, the building and even the life of the furnace operator.

Better Products

Moisture can cause dramatic shifts in the cooling curve of oil, resulting in unwanted metallurgical variations. The AQUA-SENSE system constantly monitors moisture levels, and will sound an alarm and give a visual signal when predetermined limits have been exceeded. Early detection and correction before moisture alters the cooling curve of the oil can stop production and quality control problems before they begin.